AN innovative powder-free IBC transfer realized by the joint forces of Pharma Hub and CSV Containment for connecting the receiver IBC and perform the transfer in a fully powder-free condition.

The powder-free IBC transfer application, created by the joint know-how of the two companies belonging to CSV Life Science Group and specialised in Process Applications and Containment Solutions, has been completed by using a new special unloading equipment:

- Lifting and Docking IBCi_Platform

- Wheeled detachable IBC station

- The New Double Gate Valve (GG valve)

- The control system

The IBCi_platform:

- Guarantees a perfect mechanical IBC positioning and eliminates operator errors, as the IBC positioning is fully guided

- Automatically interlocks the IBC transfer

- Allows perfect docking to the equipment to be discharged by the operator

- Automatically lifts the IBC containing the discharge product up and down

Wheeled detachable IBC station:

- IBC equipped with special equipment and vibrator to facilitate unloading operations by distributing uniformly the product inside the IBC itself

- The customizable trolley support allows to lift the IBC to simplify the interfacing operations to other equipment

- The trolley support is equipped with wheels as well as with interface in order to be moved by using forklift and manual pallet truck

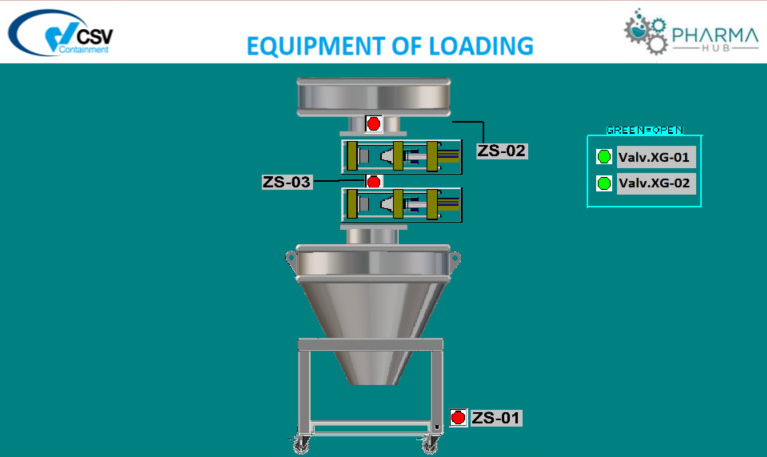

The Double Gate Valve:

- Allows to interface the IBC to the equipment to be discharged

- Allows a powder-free flow thanks to this No Butterfly Lens configuration

- Provides a powder-free transfer thanks to Double Gate configuration: passive GATE on the IBC and Active Gate on the bottom of the equipment

- Inerting GAS proof

The control system:

- Automatically manages the docking, opening, closing and unlocking sequences

- Is suitable for electrically classified area as ATEX rated for Gases and Powders

- Signals exchanging with equipment to be discharged

The Double Gate Valve

Automation and repeatability.

Pharma Hub’s equipment is provided with a Double Gate Valve produced by Csv Containment. This solution allows to connect the IBC receiver and perform a fully powder-free transfer. Automation and repeatability can allow no powder residuals during coupling transfer and IBC separation.This Intermediate Bulk Container with valve coupling is a safe material handling solution for pharmaceutical production facilities.

Features:

- The IBC is provided with antistatic and pivotal wheels equipped with brakes.

- An Automatic Double Gate Valve, on the top, equipped with and inflatable seal secures the IBC to the offloading point and tights the discharging circuit during the powder transfer avoiding dusty effect and dispersion in the surrounding.

- The Gate has a second seal, needed to close the gap created when the gate opens in the discharging chute, in order to avoid powder penetration in the cassette itself.

- A Control Panel (positioned on the offloading point) allows to command the IBC docking to the discharging chute as well as the opening and closing of the gate valve

- IBC perfect positioning secured by a mechanical device guide on the floor and on the discharging chute bottom profile

- Proximity switches communicate to the control panel the following status: IBC positioning – IBC docking

- Equipment butterfly valve condition.

- The gate valve metallic part made of AISI316L

- The inflatable seal is available in two materials: silicone or EPDM.

- Pneumatic Pistons and control panel in stainless steel made

- ATEX rating

- For the inside is suitable for Zone 1,21

- For the outside is suitable for Zone 2,22

- 7” touch screen HMI to control system status, check interfacing sequences and also to configure inertization parameters (optional)

IBC transfer top