The turbo-emulsifier is a machine designed for processing emulsions, by mixing liquids and viscous products, and dispersing powders and granules.

According to the specific product processed by the client, Pharma Hub is able to design customized machineries that can perform very different processes, up to the consistency of 20,000 cP (centipoise).

For instance, in case of processes in which the operator must frequently add additives at fixed time intervals, our project engineers have designed a system that through the Venturi effect ejector charges the excipient from the hopper directly into the product that will then be mixed.

Thanks to its special design aimed at minimizing product losses, the turbo-emulsifier allows to fully take advantage of the processes and, in addition, can be easily and completely washed, drained and dried.

Following the CSV Life Science Group philosophy, Pharma Hub can adapt any machinery to the client’s needs also paying attention to the existing utilities and satisfying particular production requirements.

For instance, in order to meet temperature requirements, the electrical tracing can be made on the lines to heat the pipes, or the thermostatting system and the electrical panel can be compacted and enclosed inside the technical compartment of the machine to reduce its dimensions, if the installation space is particularly limited. Moreover, also the intuitive control system, realized with a touch screen, of each machine can be designed according to project specifications.

Pharma Hub offers a complete experience thanks to the validation teams that guarantee, from the initial Fat up to Sat at customer’s site, a state of qualification of the machine consistent with all the standards of the Pharma world.

The equipment consists of:

- A liftable double-walled vessel made in stainless steel AISI 316L and Ra<0,5um

- Vertical anchor agitator

- In-line mixer for product dispersion, homogenization and emulsion

- Rotary lobe pump for transferring viscous products

- Heating and cooling thermostatting circuit

- Electric tracking system for temperature maintenance on process lines

- Washing circuit (CIP)

The vessel is first loaded with oily products which are heated and fluidized inside the vessel at a temperature of 70°C. Subsequently, a controlled flow of hot osmotized water is introduced.

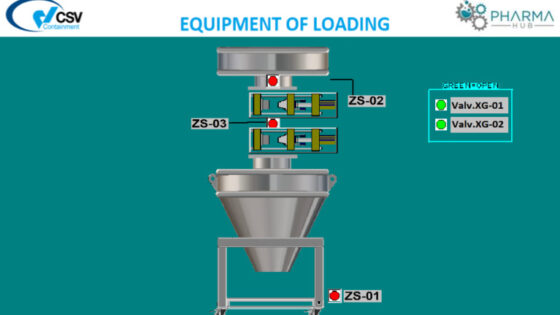

Once loaded inside the reactor, the solution is sucked in by the mixer and pushed by the lobe pump. The solution is passed through a Venturi effect ejector that generates a vacuum in its suction pipe, which allows the loading of additional additives or excipients needed for the process. The solution is recirculated into the vessel under the push of the lobe pump through the recirculation circuit.

The vertical agitator rotates inside the vessel at low speed making it possible to change and mix the product. The conformation of the agitator removes the product adhered to the walls. The product re-enters the mixer from the vessel lateral outlet and, aided by the push of the lobe pump, returns to the vessel through the recirculation pipe. Depending on the batch size being processed, it is possible to use either the bottom or the top recirculation pipe.

On the vessel lid there are:

- An agitator

- A handhole with a warning light

- Safety and vacuum-breaker valves

- Osmotized water inlet line

- Washing water inlet line with nozzles for CIP cleaning

The vessel is lifted through the piston linear actuators. The vessel has a thermostatting jacket. The system therefore allows the product to be both heated and cooled. Once the desired product quality has been reached, the product can be offloaded in an external vessel.

On the lid of the vessel there are some spray-balls likely to cover the entire vessel inner surface. The washing water is introduced through automatic line of softened water.

In addition to the vessel, also the mixer, the lobe pump and the transfer pipe can be washed. On the equipment there are placed some drainage points for water offloading.

The turbo-emulsifier control system regulates the equipment automation making the processes reliable and reproducible through the specific operator interface (HMI). The software on the operator panel is managed in pages, where on each page different functions are assigned to specific areas of the screen. The PLC software is responsible for manage completely the system logic and all related functions.

The control functions of the plant are divided into separate pages, each of which is structured into several areas of action. The control panel will be touch-screen type, without fixed keys but with programmable pressure areas in all pages.